Modern Lightweight MCM Split Brick presents the original surface of natural environment,without destroying natural environment mine.

In construction field, MCM is applied primarily in exterior walls, park trails, canals, plank roads, interior walls, background walls, ceilings, bathroom, balcony, elevator lobby, ships and furniture. Ceramic tile is used mainly in indoor floor, kitchen, bathroom, balcony and elevator lobby.

Size :

240x60x2.5(±0.5)mmThickness :

3-5mmColor :

Multiple colour, other colors can be customizedMaterial :

MCMProduct Origin :

Zhuhai City, ChinaModern Lightweight MCM Flexible Split Brick Decorative Tile

1. Light weight and high safety.

2. Low carbon, environmentally friendly and recyclable.

3. Excellent chemical stability, acid and alkali resistance, self-cleaning, weather resistance, and anti-aging.

4. Flame retardant, smokeless, and excellent fire retardant properties.

5. Intelligent breathability, waterproof, mildew-proof and crack-proof.

6. Excellent flexibility, strong peel strength and impact resistance.

7. Easy construction and low labor cost.

8. Strong three-dimensional effect, diverse colors, and natural effects.

| Size | 240x60x2.5(±0.5)mm |

| Dimensional Stability | ±0.5% |

| Thickness | 3-5mm |

| Color | Blacks, Brown, Grays, Oranges, Reds, Whites, Yellows, More Colors Can Be Customized |

| Material | MCM |

| Application | Interior Wall Decoration, Exterior Wall Decoration, High-rise Buildings, Irregular Structures, School, Office, Hospital, Hotel, Swimming Pool, Kitchen, Toilet, Etc. |

| Water Absorbing Capacity | <0.1 With European Indicators |

| Flexible | Soft and crack-free |

| Fast Construction | Easy Install, Even can be pasted onto the original wall or tiles directly. |

| Safe & healthy | Non-toxic, Non VOC, Eco-friendly, Environmental friendly |

| Fireproof | A-grade, No Naked Flame, No Dense Smoke |

| Waterproof | Dump proof, Stain Resistance & Self-cleaning |

| Breathable | Microporous Structure, Water-repellent and Air Permeability |

| Service Life | 50+ Years |

|

|

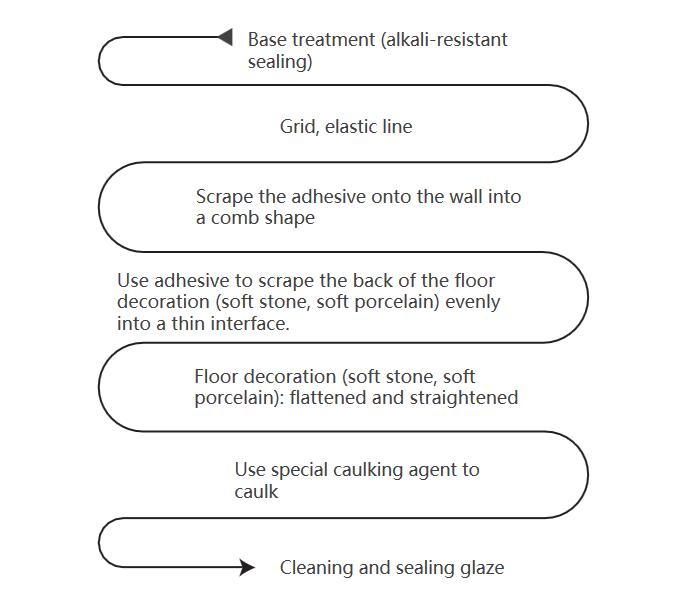

It is advisable to use the matching adhesive and scrape the slurry on the back of the product. It is recommended to leave a 6-7mm gap. It is advisable to use the matching caulking agent to fill the gaps and hook the concave seams.

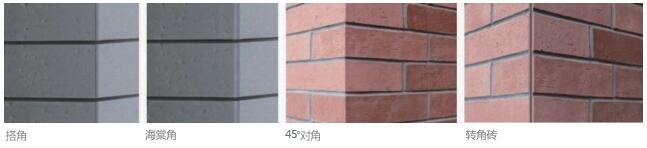

Pasting requirements for external corners, internal corners and windowsills

Soft porcelain tile series product construction flow chart

Soft porcelain tile series product construction instructions

Soft porcelain tile series product construction tools

|

|